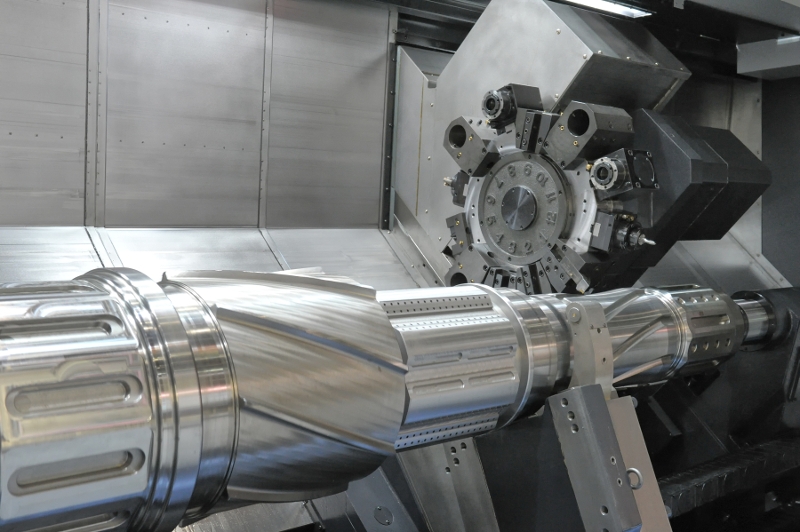

Our offer at the level of cutting services is available to customers who purchase our steels but also by subcontracting only the customer's steel cutting service.

- About us

-

Products

- Steels and Alloys

- Plastic Injection Mould Steels

- Cold Work Tool Steels

- Hot Work Tool Steels

- High-Speed Steels

- Non-Ferrous Alloys for Moulds and General Mechanics

- Structural Carbon Steels

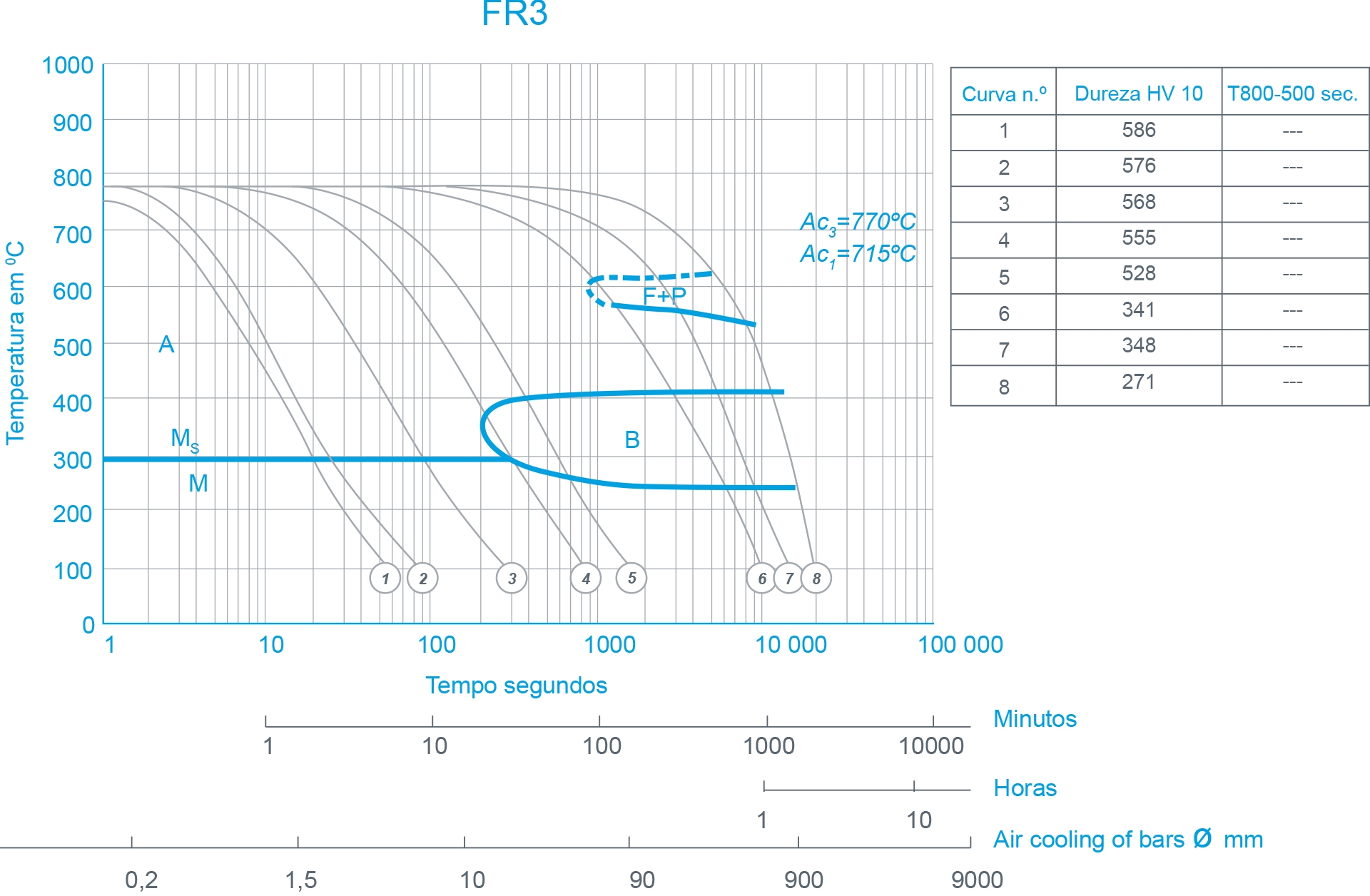

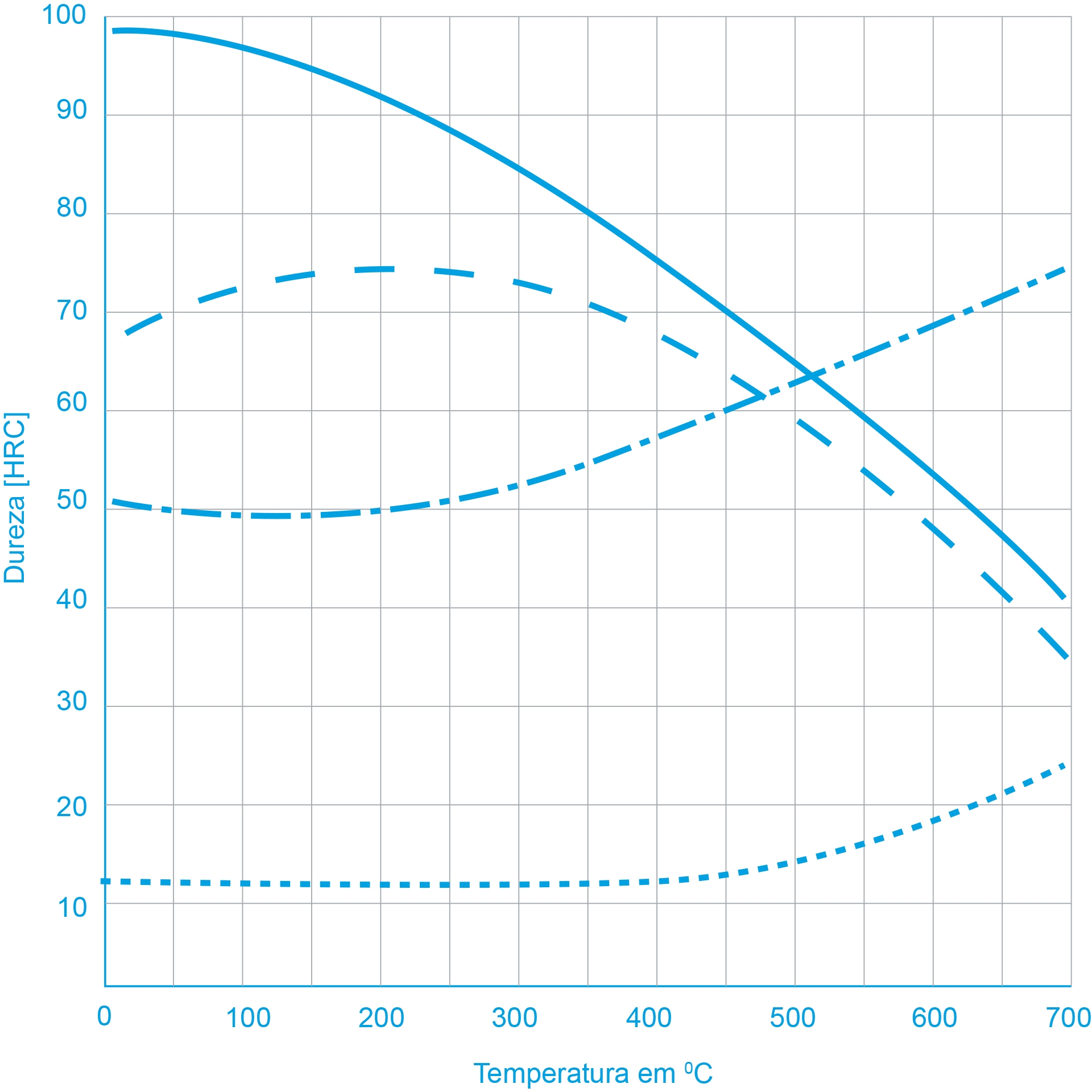

- Structural Alloyed Steels

- Easy Cut Structural Steels

- Case-Hardened Steels

- High-Strength, Wear Resistant and Carbon Steel Sheets

- Stainless Steels, Nickel Alloys and Titanium

- Cast Iron

- Services

- Applications

- Media

- Contacts