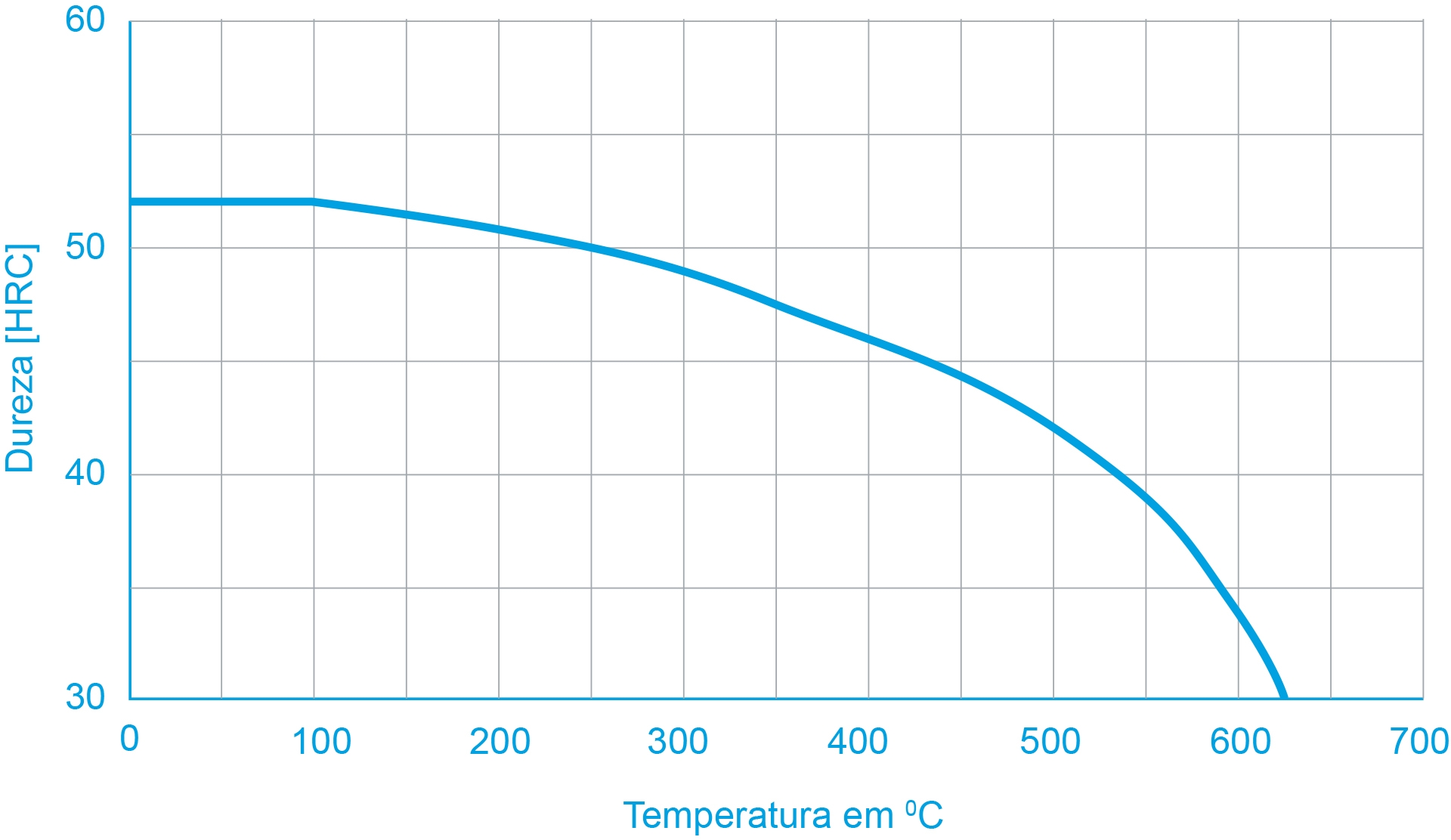

With excellent machinability and very good polishing, the manufacturing time of the tool is considerably reduced, easily allowing the fulfilment of the deadlines for its customers. It is a recent steel, designed for plastic injection moulds with numerous advantages. From the excellent machinability, allowing for shorter machining times, the ease of welding (without the need for preheating and subsequent heat treatment), making easier the maintenance and design changes of the tools without difficulty. The combination of high hardness and toughness allows the manufacture of moulds with indentation resistance and less risk of unexpected failure, making it a more durable and reliable tool. The reduced content of inclusions and their fine structure, allows an excellent superficial polishing to be obtained quickly.