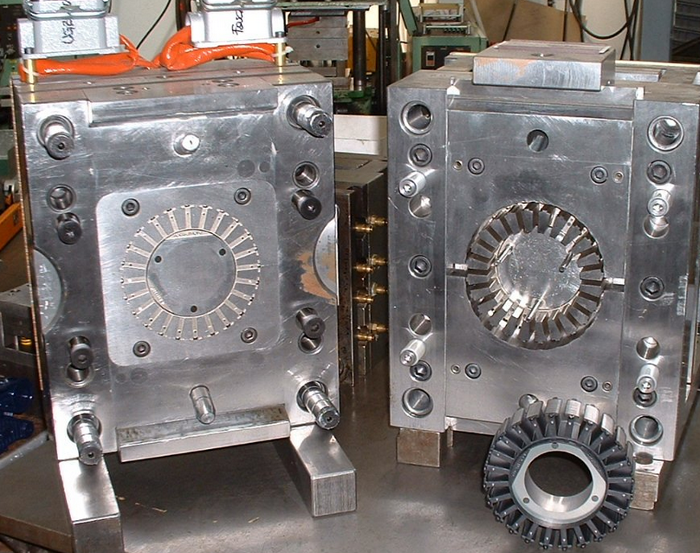

Electro Slag Remelted (ESR) steel with an exceptional combination of high ductility and hardness it is ideal for applications in injection moulding of plastics with fibre glass and/or highly abrasive reinforcements. The advantages are numerous: durability of the mould details in the injection of reinforced plastics, longer series and suitability for the compression moulding. With durability and high abrasive wear resistance, longer tool life, good surface treatment properties and very good temperability (guaranteed properties throughout the entire section).