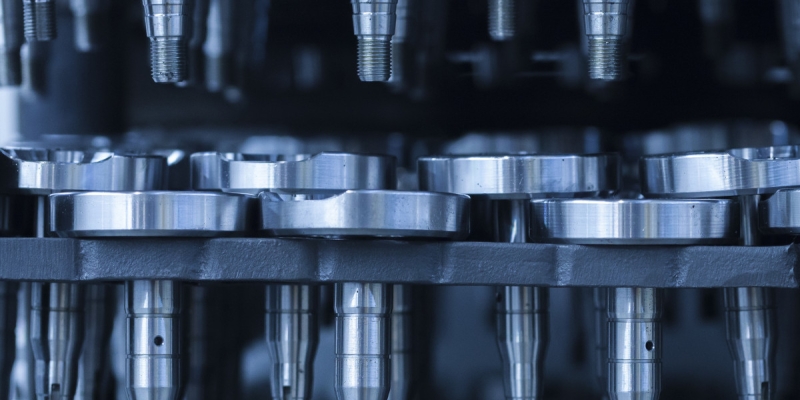

Surface hardening heat treatments especially suitable for gears, pins and bushes. It can be also applied over other types of machine parts and low cost tools.

This specific steels heat treatment, consists in the surface part enrichment with carbon (carburizing) or carbon + nitrogen (carbonitriding), by exposing the parts to a controlled atmosphere. After enrichment, parts are oil quenched to get high surface hardness (58-62 HRC). This allows the parts to have good wear-resistance as opposed to the core that has reduced hardness, capable to maintain good part tenacity.

As high temperatures are used before rapid cooling, this kind of heat treatment is responsible for dimensional deviations. Final corrections must be performed.

There are two available technologies (controlled atmosphere or vacuum furnaces). Low pressure (vacuum) technology ensures superior surface quality and reproducibility, compared to conventional furnaces. The most common treatments has following characteristics:

| Class |

Application |

Material |

Surface Hardness |

Layer mm* |

| Carburizing steels |

Strands

Gears

Bushes

|

RMC16 |

58-62 HRC |

0,3 - 0,5 |

| RMC20 |

0,5 - 0,7 |

| G15 Special |

0,7 - 1,0 |

| Carbonitriding |

Wear |

To the carbon |

>500 HV |

0,05 - 0,15 |

| 0,1 - 0,3 |

| 0,3 - 0,6 |

| <0,8 |

*most common thicknesses